The patented* Chip Trapper offers a fast, easy way to clean chips, swarf and shavings out of used coolants and other liquids. The Chip Trapper vacuums the coolant or liquid that is filled with debris and traps all the solids in a reusable filter bag. Only the liquid pumps back out. It is ideal for use on machines with sumps, parts washers, tanks and storage containers of contaminated liquids.

The Chip Trapper uses EXAIR’s compressed air powered Reversible Drum Vac (included) that can fill or empty a 55 gallon drum in less than two minutes. Simply set the Reversible Drum Vac pump and directional flow control valve on top of the drum to “fill” for it to quickly vacuum the liquid with solids. Once the sump, pit or tank is empty, set the pump and directional valve to “empty” for it to pump out clean coolant/liquid. All the chips and other solids are trapped inside the reusable fi lter bag of the Chip Trapper.

Chips can accumulate in the sump, restricting coolant flow.

The Chip Trapper pumps the coolant back into the sump – free of chips and debris.

Chip Trapper filters out solids from partswasher fluids.

Applications

- CNC's

- Lathes

- Saws

- Mills

- Drills

- Parts washers

- Pits

- Tanks

- Containers

- Grinders

Advantages

- Removes unwanted solids from liquid

- Recycles coolants

- No moving parts

- No motors to clog or wear out

- Self priming stainless steel pump

- Safe - no electricity

- Built-in pressure/vacuum relief

- Drum is included

- Spill free – auto safety shutoff

- Quiet

Why The Chip Trapper?

A sudden lack of coolant flow in a machining operation will likely damage the part and expensive tooling. Machine tools commonly discharge some chips and shavings into the coolant sump. As the chips accumulate and mound up, the coolant flow used to flood the part and tooling becomes restricted. Some high pressure coolant systems sound an audible alarm and abruptly shut down the machine when low coolant flow occurs. This results in downtime to fix the problem and clear the alarm. That isn't the case with standard machines where immediate damage can occur if the operator fails to spot the lack of coolant. Regular cleaning of the coolant sump with the Chip Trapper can quickly eliminate this very costly problem.

How The Chip Trapper Works

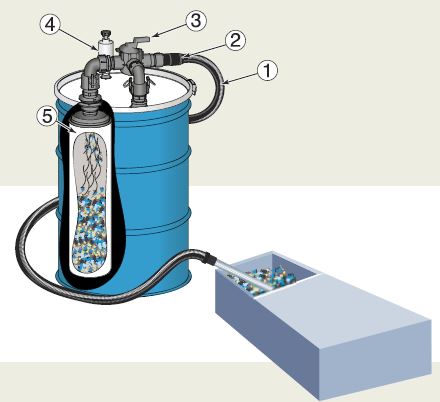

ctrworks Chip TrapperThe vacuum hose (1) is attached to the barbed connection of the Chip Trapper (2). The directional flow control valve on top of the durm (3) and know on the pump (4) are set to the "fill" position. The air supply valve is opened to permit compressed air at 80-100 PSIG (5.5 - 6.9 BAR) to flow throught the pump which pulls the liquid through the hose, then into the reusable filter bag (5). When all liquid is in the drum, the air supply is turned off. The filtered liquid can then be pumped out by setting the directional flow control valve on top of the drum and knob on the pump to the "empty" position. Once the air supply valve is opened, the air pushes the liquid back through the hose while all solids remain in the reusable filter bag.

Warning

Do not use with any material with a low flash point or with flammable liquids such as fuel oil, alcohol, mineral spirits, gasoline or kerosene.

ChipTrapper Specifications

| Pressure Supply 80 PSIG (5.5 BAR) | Air Consumption |

Water Flow Rate | Sound Level | ||

| DESCRIPTION | SCFM | SLPM | GPM | LPM | 86 dBA |

| CHIP TRAPPER | 19 | 538 | 30 | 114 | |

Built To Last

ctrbag Chip TrapperThe stainless steel pump has no motors or impellers to clog or wear out and there is no electricity or shock hazard! Safe operation is assured with a built-in pressure/vacuum relief and an automatic safety shutoff valve that prevents spills or overfilling.

BSP Threads Available - Contact Us

| Chip Trapper Systems | |

| Model # | Description |

| 6198 | 55 Gallon Chip Trapper System includes the Reversible Drum Vac pump assembly, directional flow valve, 55 gallon drum, lever lock drum lid, shutoff valve, 10' (3m) flexible vacuum hose (1-1/2"/38mm I.D.), 20' (6.1m) compressed air hose, chip wand, (2) filter bags and drum dolly. |

| 6198-30 | 30 Gallon Chip Trapper System - same as Model 6198 except includes a 30 gallon drum |

| 6198-110 | 110 Gallon Chip Trapper - same as Model 6198 except includes a 110 gallon drum. |

| 6191 | Reversible Drum Vac Only - included in all systems listed above. |

| Accessories | |||

| Model # | Description | Model # | Description |

| 901060-1 | Replacement Filter Bag, 1 micron | 901060-200 | Replacement Filter Bag, 200 micron |

| 901060 | Replacement Filter Bag, 5 micron | 901060-SP | Filter Bag Sample Pack- Includes one each 1, 25, 50, 100 & 200 micron bags |

| 901060-25 | Replacement Filter Bag, 25 micron | 6901 | Spill Recovery Kit includes a one-piece 54" (1372mm) ABS wand and 14" (356mm) double blade squeegee tool |

| 901060-50 | Replacement Filter Bag, 50 micron | ||

| 901060-100 | Replacement Filter Bag, 100 micron | 9001 | Auto Drain Filter Separator, 3/8 NPT, 65 SCFM (1,841 SLPM) |