A safe, powerful, and maintenance-free way to recover:

EXAIR's compressed air operated High Lift Reversible Drum Vac System attaches quickly to any closed head 30, 55 or 110 gallon drum.

- Coolant

- Hydraulic oils

- Liquid spills

- Sludge and chips

- Tramp oil

- Waste water

EXAIR's compressed air operated High Lift Reversible Drum Vac System attaches quickly to any closed head 30, 55 or 110 gallon drum.

Its high powered vacuum is able to lift liquids up to 15 feet and fill a 55 gallon drum in less than 85 seconds. With the simple turn of a hldvapplication HighLiftReversibleDrumVacknob, the same stainless steel pump quickly empties the drum. The High Lift Reversible Drum Vac has the extra power you need to move liquids from below grade work areas, sumps or tanks up to 15 feet!

Like all of EXAIR's industrial vacuums, the High Lift Reversible Drum Vac uses no electricity and has no moving parts which assures maintenance free operation. It is designed for continuous and heavy duty applications where electric vacuums fail due to motor wear or clogged impellers. This vacuum efficiently and safely uses the compressed air in your facility. An automatic safety shutoff valve prevents overfilling.

Applications

- Below grade coolant sumps

- Deep wells

- Underground storage tanks

- Pits

- Drains

- Deep hole broaching

- Bulk storage tanks

- Cisterns

Advantages

- No moving parts

- Maintenance free

- Stainless steel construction

- Safe-no electricity

- Built-in pressure/vacuum relief

- Compact and portable

- Installs quickly

- Spill free - auto safety shutoff

- Fits standard closed head drum

High Lift Reversible Drum Vac System Specifications

| Pressure Supply 80 PSIG (5.5 BAR) | Air Consumption |

Lift |

Water Flow Rate | Sound Level | |||

| DESCRIPTION | SCFM | SLPM | "H2O | mm Hg | GPM | LPM | 83 dBA |

| HIGH LIFT REVERSIBLE DRUM VAC | 43 | 1.218 | 180 | 336 | 30 | 114 | |

How The High Lift Reversible Drum Vac Works

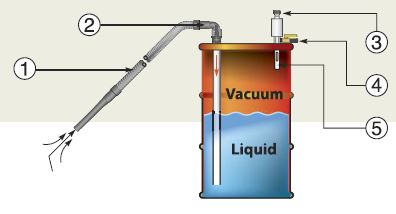

hrevwork HighLiftReversibleDrumVacThe flex hose (1) is attached to the barbed connection (2) on the Reversible Drum Vac system. The knob (3) on the High Lift Reversible Drum Vac pump is set to the "fill" position. The air supply valve (4) is opened to permit compressed air at 80-100 PSIG (5.5 - 6.9 BAR) to flow through the High Lift Reversible Drum Vac pump which pulls liquid through the flex hose and into the drum. When all liquid is in the drum, the air supply is turned of . If liquid exceeds the drum capacity,the safety shut-of valve (5) will prevent overi lling. The liquid canthen be pumped back out of the l ex hose (1) by setting the knob (3) on the High Lift Reversible Drum Vac pump to the "empty" position and opening the air supply valve.

Warning

Do not use with any material with a low flash point or with flammable liquids such as fuel oil, alcohol, mineral spirits, gasoline or kerosene.

Model 6195, Model 6195-30 and Model 6195-110 High Lift Reversible Drum Vac Systems include a vacuum hose and an aluminum wand.

Model 6295 and Model 6295-30 Deluxe High Lift Reversible Drum Vac Systems include a drum dolly, ABS spill recovery kit, vacuum hose, tool holder and all tools.

Premium High Lift Reversible Drum Vac

Systems include the drum, drum dolly, an upgrade to heavy duty aluminum tools,

ABS spill recovery kit, tool holder and air hose.

ABS spill recovery kit, tool holder and air hose.

|

|

|

| Model 6195, Model 6195-30 and Model 6195-110 High Lift Reversible Drum Vac Systems include a vacuum hose and an aluminum wand. | Model 6295 and Model 6295-30 Deluxe High Lift Reversible Drum Vac Systems include a drum dolly, ABS spill recovery kit, vacuum hose, tool holder and all tools. | Premium High Lift Reversible Drum Vac Systems include the drum, drum dolly, an upgrade to heavy duty aluminum tools, ABS spill recovery kit, tool holder and air hose. |

|

||

| Deluxe and Premium High Lift Drum Vac Systems include a drum dolly. |

||

| High Lift Reversible Drum Vac Systems | |

| Model # | Description |

| 6195 | 55 Gallon High Lift Reversible Drum Vac System includes two-way pump assembly (1/4 NPT), shutoff valve, 20' (6.1m) flexible vacuum hose (1-1/2"/38mm I.D.) with 90° quick release elbow connection, (1) aluminum wand (drum not included). |

| 6195-30 | 30 Gallon High Lift Reversible Drum Vac System - same as Model 6195 except fits a 30 gallon drum (drum not included). |

| 6195-110 | 110 Gallon High Lift Reversible Drum Vac System - same as Model 6195 except fits a 110 gallon drum (drum not included). |

| 6295 | 55 Gallon Deluxe High Lift Reversible Drum Vac System - same as Model 6195 and adds drum dolly, ABS spill recovery kit, (2) extension wands, crevice tool, skimmer tool and tool holder (drum not included). |

| 6295-30 | 30 Gallon Deluxe High Lift Reversible Drum Vac System - same as Model 6295 except fits 30 gallon drum (drum not included). |

| 6395 | 55 Gallon Premium High Lift Reversible Drum Vac System - same as Model 6195 and adds the 55 gallon drum with lock ring and lid, drum dolly, ABS spill recovery kit, 11" (279mm) and 24" (610mm) aluminum crevice tools, skimmer tool, tool holder and 20' (6.1m) air hose. |

| 6395-30 | 30 Gallon Premium High Lift Reversible Drum Vac System - same as Model 6395 except includes a 30 gallon drum. |

| 6395-110 | 110 Gallon Premium High Lift Reversible Drum Vac System - same as Model 6395 except includes a 110 gallon drum. |

| 6095 | High Lift Reversible Drum Vac Only - included in all systems listed above. |

| Accessories | |||

| Model # | Description | Model # | Description |

| 9001 | Auto Drain Filter Separator, 3/8 NPT, 65 SCFM (1,841 SLPM) | 901071 | Heavy Duty Aluminum Tools plus Tool Holder |

| 9006 | Oil Removal Filter, 3/4 NPT, 50-150 SCFM (1,416-4,248 SLPM) | 9041-30 | 30 Gallon Drum Dolly |

| 901067-30 | 30 Gallon Drum with lock ring and lid | 9041 | 55 Gallon Drum Dolly |

| 901067 | 55 Gallon Drum with lock ring and lid | 9041-110 | 110 Gallon Drum Dolly |

| 901067-110 | 110 Gallon Drum with lock ring and lid | 6901 | Spill Recovery Kit includes a one-piece 54" (1372mm) ABS wand and 14" (356mm) double blade squeegee tool. |

| 6569-20 | 20'(6.1m) Flexible Vacuum Hose (1-1/2"/38mm I.D.) | 901176 | Magnetic Tool Holder |