Air Amplifiers

Super Air Amplifiers are efficient & have the highest amplification ratios of all. Super Air amplifiers are compact, lightweight, portable & have no moving parts, assuring maintenance –free operation.

EXAIR Adjustable Air Amplifier is used for a variety of applications - either aluminum or stainless steel for high temperature (400°F/204°C) and corrosive environments. Adjustable Air Amplifier is easy to mount and have good amplification ratios.

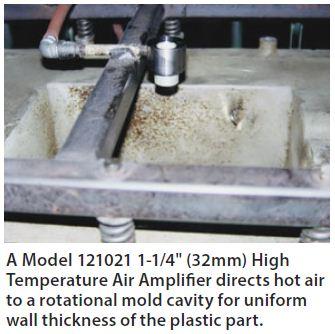

The model 121021 High Temperature Air Amplifier was developed for moving hot air and to be able withstand high temperature ambient conditions.

Air Amplifier Overview

What Are Air Amplifiers?

An uncomplicated, inexpensive way to propel, smokes, fumes & light materials. Air Amplifiers are bladeless, motor less which can be used for cooling, extracting, drying and ventilating in process, food and manufacturing industries. Using a small volume of compressed air as the power source, it utilise the “Coanda” effect to draw larger volumes of ambient air into the device to amplify the air flow by up to 25 times.

Why Air Amplifiers?

Air amplifiers are compact, lightweight, portable & have no moving parts, assuring maintenance –free operation. Air amplifier is easy to mount and maintain reducing both compressed air consumption and noise levels. It takes energy from a small volume of compressed air to produce a high velocity, high volume, low pressure output air flow. Both the inlet (vacuum intake) and discharge ends of the Air Amplifiers may be ducted for light material and fume conveying applications. Care must be taken to avoid unnecessary restrictions that will cause back pressure or suction resistance that will reduce performance levels. The back pressure and resistance should be kept to less than 2" of water column. The force, flow&vaccum can be easily controlled.

Applications

- Vent welding smoke

- Cool hot parts

- Dry wet parts

- Clean machined parts

- Distribute heat in molds/ovens

- Ventilate confined areas

- Dust collection

- Exhaust tank fumes

Advantages

Compared to Fans:

- Compact, lightweight, portable

- No electricity

- No moving parts - no maintenace

- Ends are easily ducted

- Instant on/off

- Variable force and flow

- No RF interference

Compared to Venturis and Ejectors:

- More air with lower compressed air consumption

- Higher flow amplification

- No internal obstructions

- Meets OSHA pressure and noise requirements

- Quiet

How Air Amplifiers Work

Compressed air flows through the air inlet (1) into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity. This primary air stream adheres to the coanda profile (4), which directs it toward the outlet. A low pressure area is created at the center (5), inducing a high volume flow of surrounding air in to the primary airstream. The combined flow of primary and surrounding air exhausts from the Air Amplifier in a high volume, high velocity flow.

Super Air Amplifiers : have the highest amplification ratios and are the most efficient of all Air Amplifiers.

Adjustable Air Amplifiers : have good amplification ratios and are very easy to use.